The sustainability of the automotive industry is dependent on the further development of electric vehicles. This of course was not always the case, less than ten years ago EVs were thought of as an unprofitable area for car manufacturers. Today however, EVs have reached 10% of new car sales, the sale of combustion engines banned in the UK, Canada, California, and the EU by the end of the 2030’s, and it is expected that most of the car companies are going to be predominantly electric by 2035. So, what caused this drastic shift for the automotive industry, and will it be sustainable?

The beginning of the shift towards electric vehicles began in 2015 when three major factors came into play. First of all, the technology was starting to be proven through celebrity endorsements and the acceleration in sales for the Toyota Prius. Combining that with Elon Musk’s already established Tesla Roadster and the Nissan Leaf, which showed fully electric vehicles could work. It showed both the consumers and the automotive companies that this could be sustainable in the long run.

Solidifying the shift towards electric vehicles came from the 2015 diesel gate scandal, which exposed emissions cheating in the auto industry. This scandal was completed using devices designed to pass emissions testing in the lab, but in all actuality, allowing vehicles to emit much higher levels of pollution when driving in the real world. This absolutely destroyed the public trust in combustion engines, and the car industry suffered a severe blow. This forced politicians to increase the regulations on combustion engines even more.

While there were a few issues in 2015 in terms of combustion engines, many forecasts predicted electric vehicles to be only 10% – 20% of new car sales by 2030. Today however, the bigger car manufacturers are expecting to be 100% electric by 2030. In order to reach that goal, there are short term, mid-term, and long term goals.

In the immediate future, it is expected that there will be a tightening of global tailpipe emissions regulations, increasing zero-emissions car quotas, and even greater government-led incentives. These immediate goals are driven by climate change, air pollution, and the push for a more sustainable economy. In terms of policies from the government, the US Inflation Reduction Act includes over $30 billion earmarked for tax breaks on EVs, installation of charging stations, and government vehicle procurement.

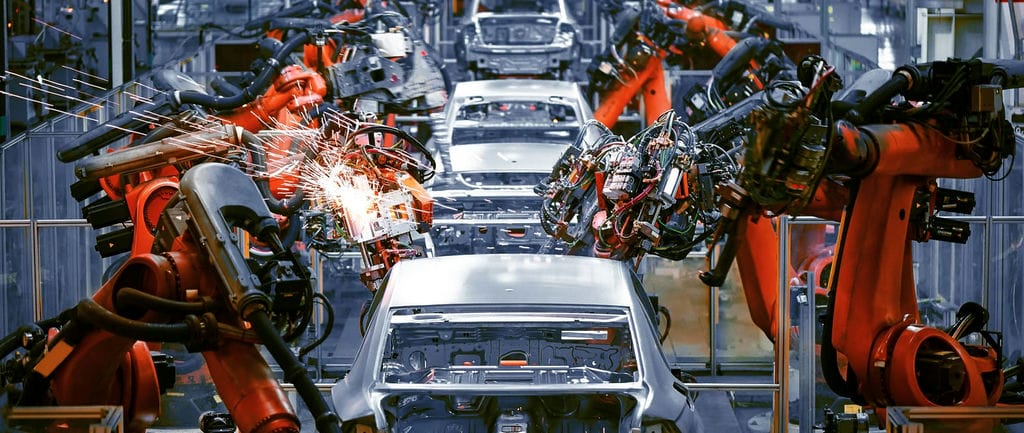

Some mid-term goals will be to improve the technology to improve the cost and performance of electric cars. As of today, the battery alone for a long-range EV is around$13,000. Producers are looking to improve battery materials, battery management systems, and production efficiencies. These improvements should quickly cut costs to around $10,000, and with next generation technology as low as $5,000.

One of the main long-term goals is to simply build up the trust people have with electric vehicles. Furthermore, the market should move towards electric vehicles to be the same price as combustion vehicles, will cost $1,000 less to run each year, have 400+ miles of range, ten-minute charging times, and many charging locations.

All of the short-term, mid-term, and long-term goals all require a sustainable market. This would include creating a product, supply-base, and an end-of-life prospect which supports the United Nations sustainable development goals (SDGs).

The invention of the lithium-ion battery revolutionized the cost of production and how efficient modern electric cars are. The current day electric cars are more than 75% efficient, while combustion engine vehicles utilize just 25% of the energy from gasoline, the rest being wasted on heat and noise. Thanks to this incredible efficiency, the electric car averages 1 tone less CO2 emission for each year of driving, even if it is charged partly by fossil fuels. Because of this, an EV will save more than 10 tonnes of CO2 compared to the equivalent combustion engine car.

Of course, with this increase in production of the electric vehicle, the supply chain can become quite competitive. To ensure a sustainable supply, car manufacturers need a heavy supply of lithium, nickel, cobalt, and copper. Thankfully these resources are easily available right on Earth’s crust. In order to replace 1.4 billion of the cars on the road today with EVs, it is estimated that it would consume about 15% of the Earth’s lithium. There is some concern about mining some of the materials, like cobalt since 70% of the supply accounts for a third of the national GDP for the Democratic Republic of Congo. It is important to improve the mining techniques and operations before the electric vehicles are in more of a demand.

The world is pushing towards sustainability and a circular economy, so the end-of-life treatment of cars is much more important. Many studies have shown that the EV batteries will outlast the vehicle, by the next decade there will be an increased need to close the loop on vehicle manufacturing. There are three main options to choose from: reusing, recycling, and reducing.

Reusing is the first option, where EV batteries are refurbished to 70% of original performance and even re-purposed in residential or energy storage applications.

Recycling the spent batteries can be beneficial by extracting the invaluable metals already available and viable. Mixing regulation, incentivization, and infrastructure will enable the future of the battery recycling industry to expand.

Reducing is the final option, where societies place less of an emphasis on driving to destinations, and instead use public transport, walking, or riding a bike.

Despite being around for many years, electric vehicles are only just beginning to make a dent in gasoline-powered vehicles. This shift has started to occur thanks to a few different factors like the diesel scandal, and famous endorsements. This shift is expected to continue within the next decade, and it is expected that more than half of the vehicles on the road will be electric vehicles.